Understanding Particle Release from NOVA Antimicrobial Coatings

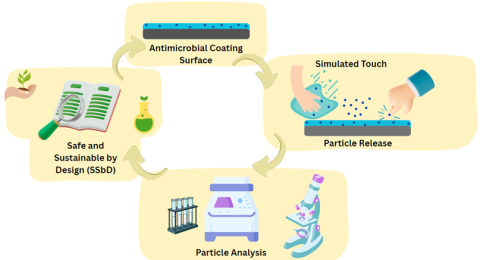

NOVA is developing next generation antimicrobial coatings to help prevent pathogen spreading and make everyday environments safer, from medical equipment and public transport, handles to doors and other frequently touched surfaces in public buildings. These innovative materials are designed to prevent the spread of microorganisms while remaining safe for users and environmentally responsible. Before such coatings can be used widely, we must make sure they do not harm the environment. We have to check whether any particles might break off during use, build up in nature, or cause unintended effects on health and wildlife. One of the key steps in this effort is to understand how these coatings behave under real-life conditions. When surfaces are frequently touched or cleaned, small amounts of material may detach or release from the surfaces. By studying these processes, we can ensure that our coatings remain effective, stable, and safe throughout their entire life cycle.

NOVA is divided into 8 work packages. Within work package 6 (Sustainability assessments of nanocoatings), Empa refined a lab test to check how much material might be rubbed off antimicrobial coatings. We used the NOVA light-activated coatings that contain ultraviolet radiating (UV) upconverters as a case study. These coatings turn visible light into UV light. UV light blocks spreading pathogens by attacking their DNA, without using traditional chemical agents. This approach offers a durable and biocidal-free route to antimicrobial performance.

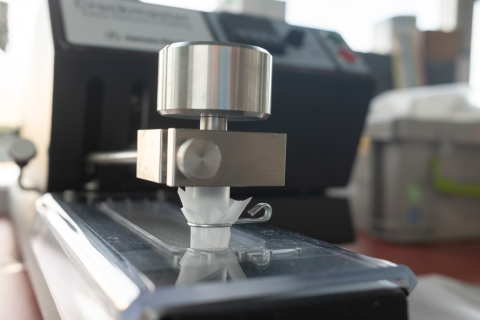

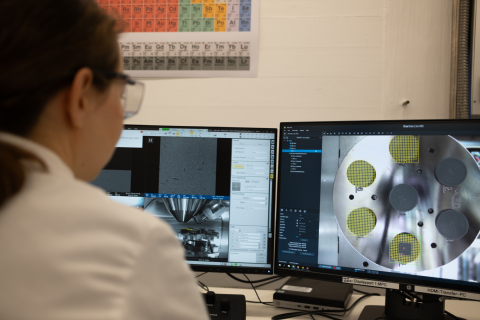

We used a testing device that mimics everyday touch and cleaning to reproduce gentle touch and cleaning. The method allows variation of parameters such as wipe material and moisture conditions (e.g., dry, wetted with artificial sweat or cleaning agents), making it possible to closely mimic touch, cleaning and disinfection. Following these tests, any released material was collected and analyzed using advanced analytical and microscopic techniques, including mass spectrometry and electron microscopy. Mass spectroscopy works by using high temperature plasma to turn samples into ions to measure which elements are present and in what quantity. Electron microscopy, in turn, is able to create high-resolution images that reveal the surface structure in great detail. Together, these tools allow us to determine not only how much particles may detach during use but also its composition and morphology. These insights help us to better understand the stability of the upconverter particles and their interaction with the coating matrix over time, contributing valuable knowledge to assessing whether such antimicrobial coating could pose any release-related concerns during normal use or cleaning.

These results will be contributing to the work towards Safe and Sustainable by Design (SSbD) principles. This work supports NOVA’s commitment to designing coatings that combine performance, safety, and sustainability. Future studies will expand this approach by exploring different coatings, and environmental conditions, further strengthening the project’s contribution to safe innovation in antimicrobial surface technologies.

ICP-MS © Empa